Create Safe, Flexible, and Productive Workspaces.

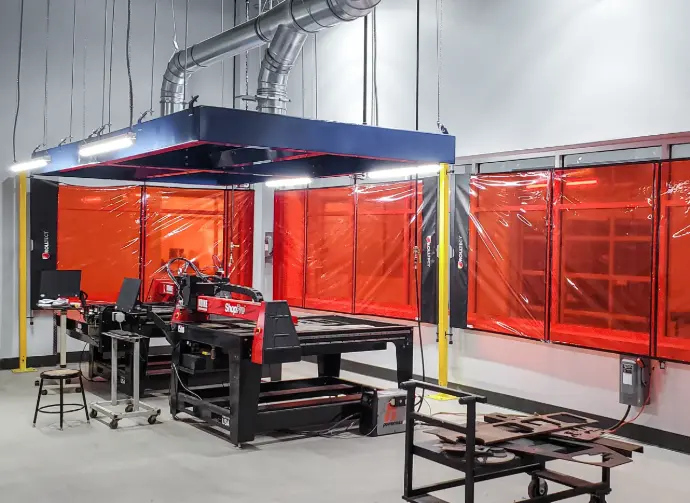

In welding and fabrication, safety is non-negotiable. PWS partners with Shaver Industries, a leader in industrial safety solutions, to provide comprehensive protection against arc flash, sparks, heat, and dangerous laser radiation.

Our range of Shaver Industries curtains, including the versatile ROLLTect welding curtains and cutting-edge LZRTect laser safety solutions, empowers you to define secure work zones, protect bystanders, and enhance overall workshop efficiency, all while complying with essential safety standards.

ROLLTect Welding Curtains: Robust Protection & Workspace Flexibility.

ROLLTect curtains are engineered to provide durable, fire-retardant protection against the hazards of arc welding, grinding, and cutting. Their flexible design allows for adaptable workspace segregation, ensuring welder and bystander safety without compromising productivity.

Key Features & Benefits:

- UV/IR Protection: Shields eyes and skin from harmful welding arc radiation (available in various EN-159 certified shades).

- Spark & Spatter Containment: Prevents sparks and molten metal from reaching other areas, reducing fire risk and damage.

- High Durability: Made from robust, flame-retardant PVC or heavy-duty canvas for longevity.

- Visibility Options: Translucent coloured strips (e.g., orange, green, yellow) allow for safe observation of welding activity.

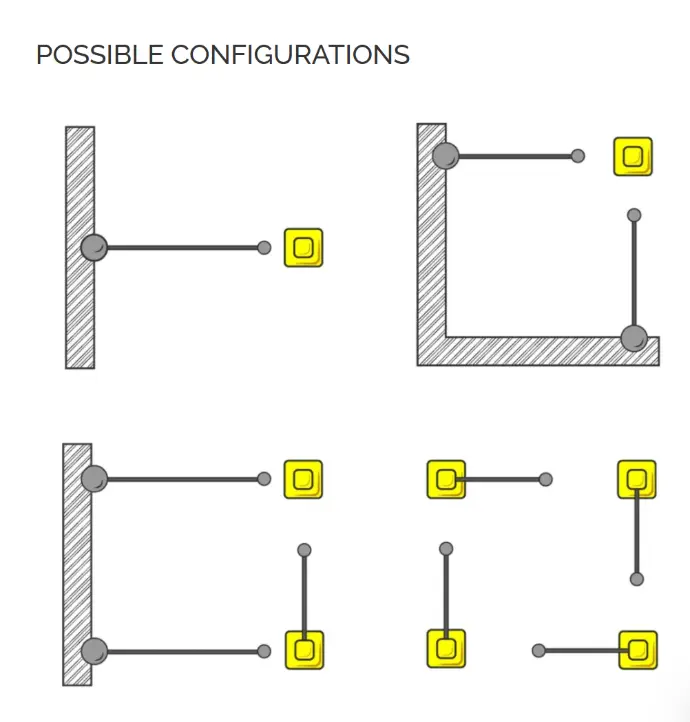

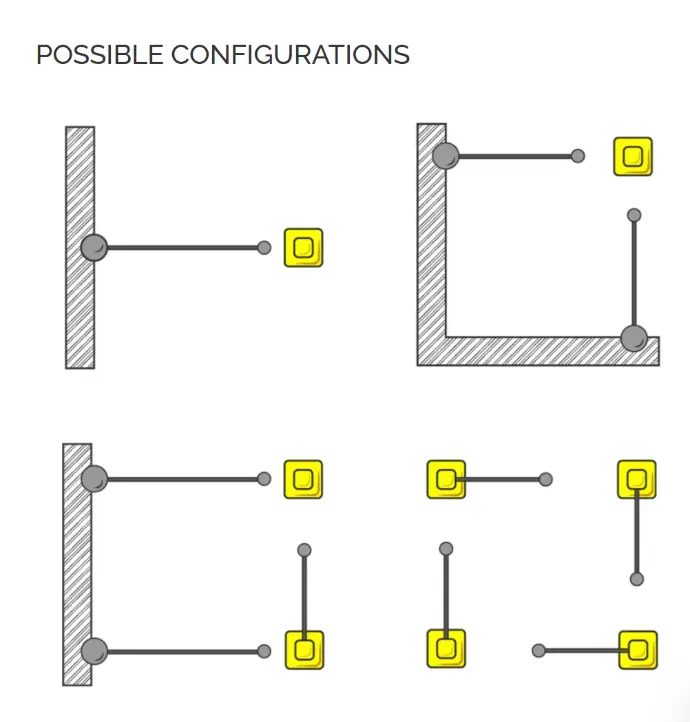

- Customisable Solutions: Available as strip curtains, solid panels, or retractable systems to fit any bay size or workflow

.

- Noise & Dust Reduction: Contributes to a cleaner, quieter, and more organized workspace.

Applications: General fabrication workshops, educational facilities, automotive repair, designated welding bays, grinding and cutting zones.

LZRTect: Specialised Laser Safety Curtains for High-Tech Environments

As laser technology advances, so does the need for specialized protection. LZRTect curtains are designed to provide certified, reliable barriers against direct and diffuse laser radiation, creating safe enclosures for laser welding, cutting, and additive manufacturing processes.

Key Features & Benefits:

- Certified Laser Protection: Engineered to meet specific laser safety standards (e.g., compliant with ANSI Z136, EN 60825, CE for relevant wavelengths).

-

Targeted Wavelength Protection: Materials are selected to block specific laser wavelengths common in industrial applications (e.g., fiber, CO2, Nd:YAG lasers).

-

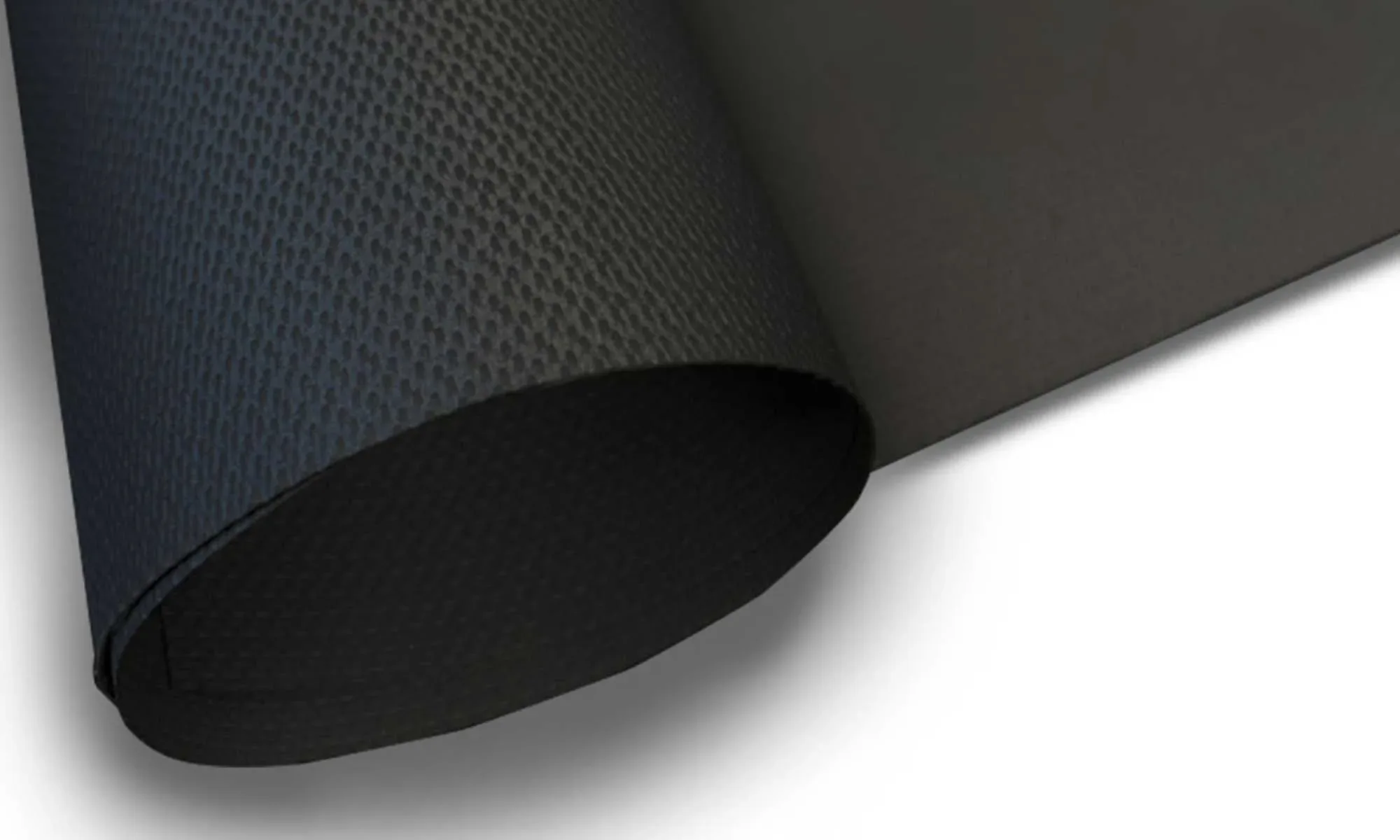

High-Density Materials: Constructed from specialized laser-blocking fabrics (e.g., silicone-coated glass fibre) for maximum absorption.

-

Passive Safety Integration: Can be integrated with interlock systems for automated laser shutdown upon breach.

-

Flexible Deployment: Available in custom sizes and retractable designs for dynamic cell layouts.

Applications: Laser welding cells, robotic laser processing, additive manufacturing facilities, research & development labs using high-power lasers.

View ANSI Z136.7-2020 Certification View EN12254 2010 Certification

Certified Protection: Meeting NZ & International Safety Standards.

At PWS, we ensure our safety solutions meet rigorous compliance requirements. Both ROLLTect welding curtains and LZRTect laser safety curtains are designed and manufactured to adhere to relevant New Zealand and international safety standards, providing you with confidence in your workplace protection."

For LZRTect Laser Safety Curtains, a detailed Product Safety Assessment confirms their ability to withstand high-power laser radiation. These curtains are independently tested and certified to withstand direct laser impact , making them suitable for managing the hazards of Class 4 laser systems. This assessment is based on compliance with relevant standards including:

- AS/NZS IEC 60825.4:2023 : The local standard for laser guards, based on a risk-management approach.

- EN 12254:2010: European standard for laser workplace screens. The material achieves a protection level of AB5, withstanding a direct laser impact of 250 W/cm2 for 5 seconds without penetration.

- ANSI Z136.7-2020 : North American testing protocol, confirming resistance to a laser irradiance of 60 W/cm2 for a full 100 seconds without penetration.

- (General reference) EN 60825-1:2014: Defines laser safety classifications.

While certified performance data is provided, the end-user has the ultimate responsibility for conducting their own risk assessment and ensuring the equipment is appropriate for their specific application. Compliance is achieved when the curtain's certified performance meets or exceeds the protection level required by your site-specific risk assessment.

Download Safety Assessment PDF